PISTON RING EXCELLENCE. SINCE 1956.

LEADERS

IN PISTON RINGS

FOR LARGE BORE ENGINES

QIN is the 21st century regeneration of the piston ring market leader formerly known as Industriale Srl. We are a leading manufacturer of piston rings for 2-stroke and 4-stroke large-bore engines up to 980mm diameter. These go into marine, industrial, power generation, and rail applications worldwide.

Why QIN?

Our customers choose QIN piston rings because they know that they receive market-leading technology, with short lead times and competitive pricing.

PROCESS &

TECHNOLOGY

A leading piston ring manufacturer, QIN has developed a new production cycle that allows minimal and constant machining tolerances and has enabled total product traceability.

INdustry

EXPERTS

With more than 50 years of experience of manufacturing piston rings, we understand our customers and their end-users, and we design for both current needs and future expectations.

LARGE BORE PISTON RINGS

large bore

PISTON RINGS

COMPRESSION RINGS. OIL SCRAPER AND CONTROL RINGS.

They may not be the largest engine components, but engine piston rings remain critical to performance. Choosing them wisely will save on expensive lubricants, reduce wear and tear, and avoid expensive failures and unscheduled maintenance delays. QIN provides swift worldwide delivery from our large inventory, as well as supplying piston-ring sets in common sizes and specifications compatible with leading OEM large-bore engines.

From 160mm to 980mm cylinder bore, QIN piston rings can be found in the main engines of the planet’s largest container vessels and fastest ferries as well as the auxiliary engines of the worldwide fleet

For a compatible piston-ring set, contact us for a full list of the engine makes and models. We also manufacture and supply Anti-Polishing Rings, Flame Rings and Repair Bushes.

ENGINE PISTON RINGS

Anti-Polishing Rings, Flame Rings and Repair Bushes

INCREDIBLY DURABLE MATERIAL COMBINATIONS

MATERIAL

Refined over millions

of engine miles.

QIN engine piston rings form tight compression seals to boost engine performance. They will also reduce friction/wear and so provide savings on expensive lubricants. In addition, they can also be relied upon to transfer heat from the piston crown to the cylinder.

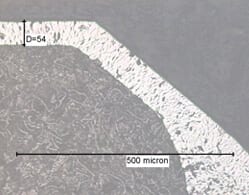

QIN offers various coating options including computer-controlled chrome ceramic galvanisation: the smoothest, hardest-wearing and least wear-inducing coating available in the market today for this size and type of piston ring.

Very few European piston ring manufacturers can offer this in-house, even fewer can do it to the highest standards, and thereby help their customers keep engine wear to an absolute minimum.

A LONG HERITAGE OF PRECISION MANUFACTURING