PISTON RINGS, FIRE BANDS & REPAIR BUSHES

PISTON RINGS

from 160mm to 980mm bore

QIN piston rings can be found in the main engines of the planet’s largest container vessels and fastest ferries as well as the auxiliary engines of the worldwide fleet. QIN piston rings are designed to operate with all fuels under the most stringent environmental conditions.

Within a piston ring set, the first rings are often referred to as compression rings and are designed to seal combustion gases and ensure no drop in pressure and associated drop in engine efficiency. The top ring which works the hardest, will normally be of the highest specification. Beneath them can be found the oil scraper and control rings which prevent oil from reaching the combustion chamber and, as the name suggests, regulate the amount of lubrication in the cylinder wall.

Typically, QIN supplies a set of rings comprising compression ring(s), oil scraper rings and oil control rings, however, on request, we can supply rings individually.

At QIN we can offer swift delivery, worldwide, from our large inventory of work in progress as well as finished ring sets in the most common sizes and specifications compatible with the large-bore engines of leading OEMs. Contact us for a full list of the engine makes and models for which we are able to provide compatible piston ring sets.

Fire bands, or anti-polishing rings, are rings inserted in the upper end of the cylinder liner in order to minimise carbon deposits building up on the higher area of the piston surface above the top compression ring.

Repair bushes or sleeves are needed when reconditioning cylinder liners’ outer surface.

QIN can manufacture all such rings in line with customer requirements

FIRE BANDS

& REPAIR BUSHES

THE HARDEST WEARING BASE MATERIALS

QIN6PE

Chemical Composition [%]

| C: 3,20 ÷ 3,50 | Cu: 0,50 ÷ 1,00 |

| Mo: 0,20 ÷ 0,45 | Mn: 0,60 ÷ 0,90 |

| P: 0,15 ÷ 0,35 | Cr: 0.20 ÷ 0,30 |

| Si: 1,85 ÷ 2,35 | S: 0,10 max |

| V: 0,05 max | Ni: 0,30 max |

| Hardness | 230 ÷ 290 HB |

| Modulus of elasticity | 90.000 ÷ 120.000 N/mm |

| Bending strength | 500 N/mm² |

QIN9S

Chemical Composition [%]

| C: 2,90 ÷ 3,40 | Cu: 0,50 ÷ 1,00 |

| Mo: 0,40 ÷ 0,75 | Mn: 0,60 ÷ 1,00 |

| P: 0,10 ÷ 0,30 | Cr: 0,10 ÷ 0,40 |

| Si: 1,70 ÷ 2,30 | S: 0,10 max |

| V: 0,05 max | Ni: 0,20 max |

| Hardness | 240 ÷ 300 HB |

| Modulus of elasticity | 95.000 ÷ 125.000 N/mm² |

| Bending strength | 600 N/mm² |

QIN27

Chemical Composition [%]

| C: 2,90 ÷ 3,90 | Cr: 0.15 max |

| Mg: 0,06 ÷ 0,12 | P: 0,10 max |

| Si: 1,80 ÷ 2,70 | Cu: 0,35 ÷ 1,00 |

| V: 0,05 max | S: 0,03 max |

| Mn: 0,80 max | Ni: 1,50 max |

| Hardness | 260 ÷ 350 HB |

| Modulus of elasticity | 140.000 ÷ 180.000 N/mm² |

| Bending strength | 1300 N/mm² |

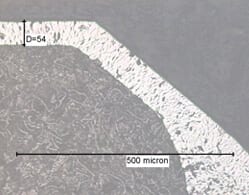

SCIENTIFICALLY ADVANCED COATINGS

QIN53 COATING

Chrome ceramic coating

Hard chrome coating

Plasma and metallic

sprayed coating

[Mo, Cu, Sn, Ni, Ni-Cr-Mo]

Three side coating

For heavily loaded rings